Many factories, be it large scale or small scale, face heavy losses if they do not track the components used in the manufacturing of their goods.

Many factories, be it large scale or small scale, face heavy losses if they do not track the components used in the manufacturing of their goods. These losses can prove detrimental in making or breaking the profit margin of that particular enterprise for the next few months.

Obviously, every business owner will like to yield heaps of profit from their business. If not, then what’s the point of doing the business. To minimize losses in the manufacturing sector, many companies have now started using Manufacturing Management Software.

Now, let’s take a look at what this thing actually is.

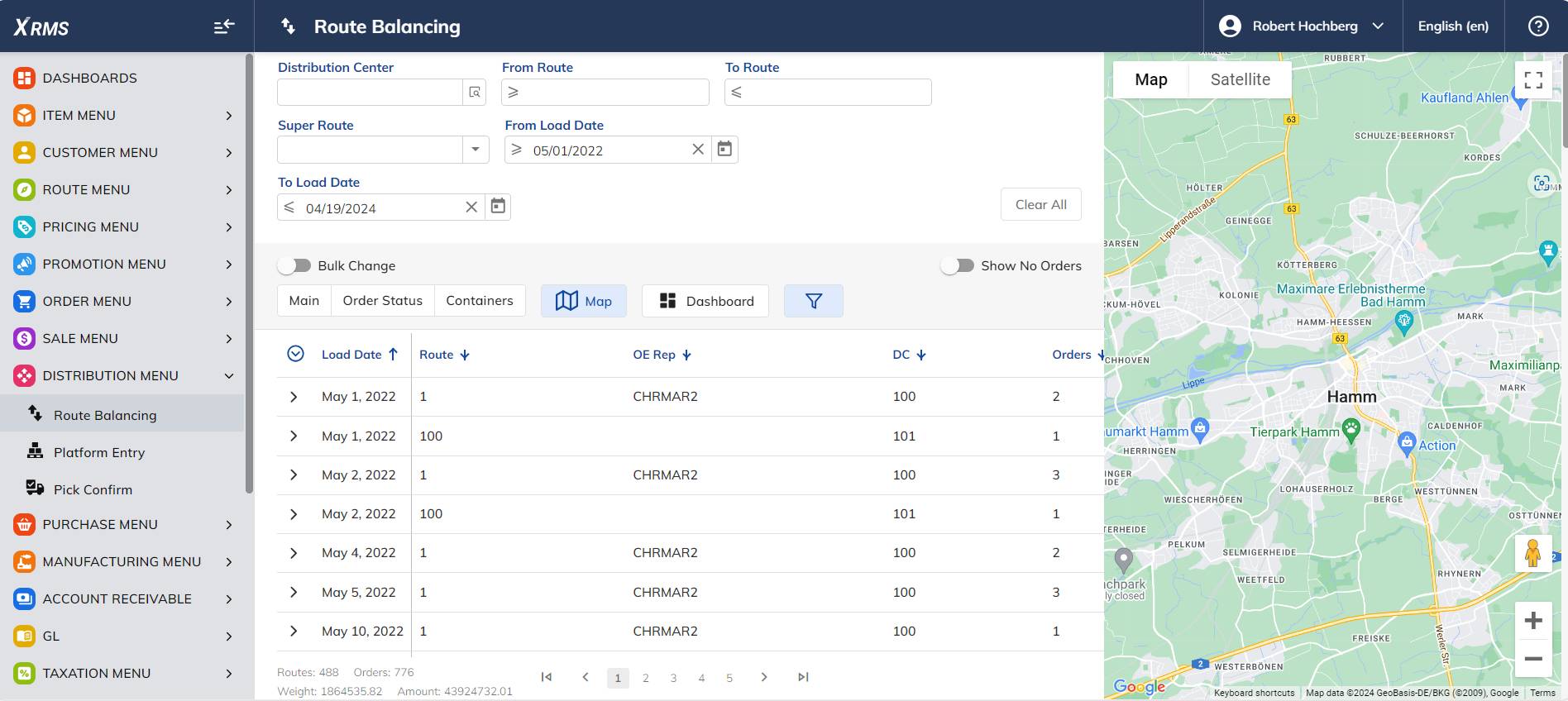

Manufacturing management software enables single or numerous factories and distribution centers to effectively manage raw materials, production, and inventories. It enables standard costing and reporting, as well as capacity planning, production scheduling, cost component monitoring, and back flushing, all of which are essential to handling today’s production system. The finished goods management module, which is connected with DRP, tracks products from the manufacturing line to the warehouse. Each of these sectors benefits from this fully functional manufacturing software. It also provides comprehensive reporting capabilities across the production system, including a variety of pre-configured reports.

To summarize, this software can efficiently keep track of:

With the help of this software, a lot of manual and time taken processes are replaced by much more streamlined and automated ones. This leads to a lot of time being saved and reduces the chances of any errors.

Businesses have a lot of things going on in the back-end, so they often look for something that gathers their data in one place in a much more streamlined manner. This software efficiently does it all and gives access to major personnel to access in real time. The ease to access data anywhere and anytime improves productivity and efficiency by a huge margin.

Imagine keeping a manual staff to record all the pre-manufacturing data manually. The risks are that it won’t be done as efficiently and systematically as software would do, and the manual labor will take a great toll on the company’s budget. Instead of going on this path, companies often opt for manufacturing management software. It allows a company to save costs and do work as efficiently as they want.

The majority of manufacturing management software is adaptable and customizable. They aren’t a “one-size-fits-all” solution. They can be adjusted to a company’s specific requirements. Not only that, but they can also adapt to the ever-changing requirements of a new company.

In the guide above, it is clear how introducing manufacturing management software can drastically improve the dynamics of your company. If you are a business owner and looking for such software for your company, contact NCS. Or fill out the form given on the link https://www.ncssuite.com/request-a-call-or-demo and our team will contact you shortly.